Future Innovations in Best Factory Technologies and Their Advantages for 2025

As we approach 2025, the landscape of factory technologies is set to undergo transformative innovations that promise to redefine efficiency, productivity, and sustainability in manufacturing. According to a recent report by McKinsey, factories that adopt advanced technologies such as IoT, AI, and robotics could see productivity gains of up to 30% and a significant reduction in operational costs. Furthermore, the World Economic Forum highlights that the integration of smart technologies in factories can lead to a 10-20% increase in energy efficiency, addressing both economic and environmental challenges. These advancements not only enhance manufacturing processes but also enable factories to adapt more swiftly to market changes and customer demands, ultimately positioning them as competitive leaders in the global market.

As we delve into the future innovations in factory technologies and their advantages, it is crucial to understand the technical specifications that will shape these developments in the coming years.

Future Trends in Automation: Transforming Efficiency in Factory Operations by 2025

As we approach 2025, the landscape of factory operations is set to undergo a significant transformation driven by advancements in automation technology. Industry reports indicate that the global market for industrial automation is projected to reach $200 billion by 2025, reflecting an annual growth rate of approximately 9.5%. This surge in investment is primarily attributed to the increasing demand for enhanced efficiency, reduced operational costs, and improved product quality. Automation technologies such as robotics, AI, and IoT are at the forefront of this evolution, allowing factories to streamline processes and minimize human error.

One major trend shaping this future is the implementation of smart factories, where interconnected systems and real-time data analytics enhance decision-making and workflow optimization. According to a 2022 report by McKinsey, organizations that adopt smart manufacturing technologies can boost productivity by up to 30% and reduce operational costs by as much as 20%. This level of efficiency not only contributes to higher profit margins but also enables manufacturers to meet the demands of an increasingly competitive marketplace. As these technologies continue to evolve, their capabilities will further empower factories to adapt quickly to changing consumer needs, solidifying automation's role as a catalyst for operational excellence.

The Role of Artificial Intelligence in Enhancing Production Processes

As we look toward 2025, the integration of artificial intelligence (AI) into manufacturing processes is set to transform traditional factory technologies significantly. Reports indicate that nearly 70% of manufacturers are already investing in AI to boost productivity and efficiency. By implementing AI-driven analytics, companies can better predict equipment failures, reducing downtime by up to 50%. According to a McKinsey study, factories leveraging AI can potentially increase their operational efficiency by 20-30%, which underscores the critical role of AI in enhancing production capabilities.

Moreover, AI's application in smart manufacturing extends to quality control and supply chain optimization. Machine learning algorithms analyze data from production lines in real-time, detecting anomalies and ensuring product consistency. A report from PwC highlights that 72% of manufacturing executives believe that AI will provide a competitive advantage in the next five years. This newfound ability to streamline processes not only enhances productivity but also reduces waste, leading to a more sustainable manufacturing model. As we advance into this new era, the synergy between AI and factory technologies is poised to deliver unprecedented advantages, shaping the future of the manufacturing landscape.

Sustainable Manufacturing: Innovations Driving Eco-Friendly Factory Technologies

The future of factory technologies is increasingly intertwined with sustainability, as industries pivot towards eco-friendly practices. According to a report by McKinsey, sustainable manufacturing could save the global economy up to $1 trillion by 2030, significantly reducing waste and improving energy efficiency. Innovative technologies such as robotics and AI are now being tailored to optimize production processes while minimizing their environmental footprints. For example, smart factories equipped with IoT sensors can monitor energy consumption in real-time, allowing for adjustments that cut energy use by as much as 20%.

Moreover, the adoption of renewable energy sources is on the rise, with a report from the International Energy Agency projecting that renewable energy could account for nearly 95% of the increase in global power capacity through 2025. Factories that integrate solar panels and wind turbines not only reduce their reliance on fossil fuels but also enhance their corporate responsibility image. Innovations like 3D printing are also contributing to sustainable practices, as they enable on-demand production that decreases inventory waste and cuts transportation emissions. These advancements are shaping a future where manufacturing processes are not just efficient but also contribute positively to the planet.

This bar chart illustrates the key advantages of various innovations in eco-friendly factory technologies expected to drive sustainable manufacturing practices by 2025. Each category highlights the potential percentage impact of advancements in renewable energy, waste reduction, water conservation, smart manufacturing, and the circular economy on eco-friendly initiatives.

Data Analytics and IoT: Revolutionizing Real-Time Performance Monitoring

The future of factory technologies is rapidly evolving, with data analytics and the Internet of Things (IoT) playing pivotal roles in enhancing real-time performance monitoring. According to a report by the International Data Corporation (IDC), the global IoT market is expected to reach $1.1 trillion by 2025, indicating a significant shift towards interconnected devices in industrial settings. This growth not only allows for streamlined processes but also empowers manufacturers to make data-driven decisions that optimize efficiency and minimize downtime.

In addition, a study by McKinsey estimates that advanced analytics can boost productivity in manufacturing by up to 20% when integrated with IoT systems. Real-time insights derived from connected sensors enable factories to monitor equipment health and operational performance continuously.

For instance, predictive maintenance facilitated by these technologies can lead to a 10-15% reduction in maintenance costs, thus transforming how manufacturers approach operations. By leveraging data analytics and IoT, factories are set to achieve unprecedented levels of agility and responsiveness, ensuring they remain competitive in an increasingly automated and data-centric landscape.

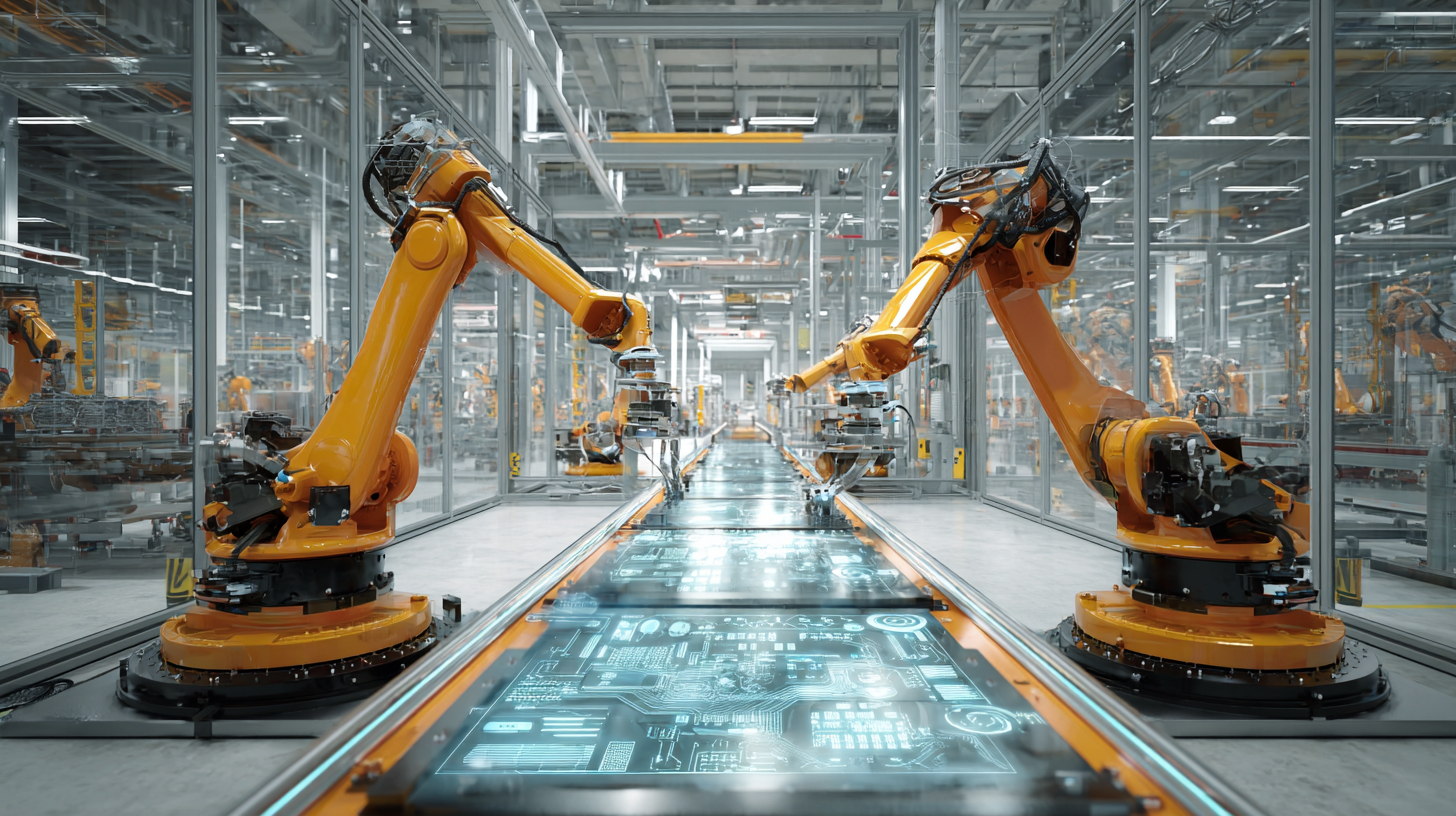

Collaborative Robotics: Human-Robot Interaction in Modern Manufacturing Systems

Collaborative robotics is revolutionizing modern manufacturing systems by enhancing human-robot interaction. As industries evolve, the integration of robots into the workforce is expected to reach a market value of $24 billion by 2025, with collaborative robots (cobots) accounting for a substantial portion of that growth. These cobots work alongside human operators, providing support in tasks that range from assembly to quality control, ensuring a seamless blend of human intuition and robotic precision.

One significant advantage of collaborative robotics is the ability to improve safety and efficiency on the production floor. According to the International Federation of Robotics, the implementation of cobots can lead to a 30% increase in productivity while reducing workplace accidents by nearly 50%. By delegating repetitive or hazardous tasks to robots, human workers can focus on more complex problem-solving roles, thus driving innovation in manufacturing processes.

**Tip:** To fully leverage the benefits of collaborative robotics, organizations should invest in training programs that help employees understand how to work effectively with these machines. Over 70% of workers expressed a need for more comprehensive training to improve human-robot collaboration, highlighting that informed staff is essential for maximizing technological advantages. Embracing a culture of continuous learning will ensure a harmonious and productive human-robot partnership in the factories of the future.

Future Innovations in Best Factory Technologies and Their Advantages for 2025 - Collaborative Robotics: Human-Robot Interaction in Modern Manufacturing Systems

| Technology | Advantages | Application Areas | Estimated Adoption by 2025 |

|---|---|---|---|

| Collaborative Robots (Cobots) | Enhanced safety, increased productivity, and flexibility in operations | Assembly lines, packaging, quality inspection | 70% |

| AI-Powered Automation | Improved decision-making, predictive maintenance, and reduced downtime | Manufacturing, supply chain management, logistics | 65% |

| Digital Twin Technology | Real-time monitoring, simulation of processes, enhanced efficiency | Product design, process optimization | 60% |

| 3D Printing | Customization, reduced waste, faster prototyping | Prototyping, spare parts manufacturing | 50% |

| Augmented Reality (AR) | Enhanced training, improved maintenance processes, better visualization | Training, remote assistance, assembly support | 55% |